Manufacturing

MKW's proud tradition is embodied by our loyal, long-serving staff, who ensure that every part of every machine meets the toughest quality standards to produce a robust and reliable solution.

Design

Our design office never stops working to develop our machinery. The way we manufacture our parts means we can make prototypes and get them into mass production extremely quickly. Every new design we produce draws on our decades of experience and expertise.

Quality control

Constant quality control and an obsessive commitment to improving our processes help us ensure that all our machinery is of the highest possible quality.

- Collating

- Brochures

- Additional and downstream devices

If you want to watch embedded videos on these pages, personal data (IP address) is sent to the operator of the video portal. It is therefore possible that the video provider stores your access and can analyse your behaviour.

When you click on the link below, a cookie is set on your computer so that the website knows that you have consented to the display of embedded videos in your browser. This cookie does not store any personal data, it only recognises that consent has been given for the videos to be displayed in your browser.

Learn more about this aspect of privacy settings on this page: Datenschutzerklärung

Show videos

Alternatively, you can use this link, which will take you directly to the video on the video provider's website: https://youtu.be/dNC1h89u_BM

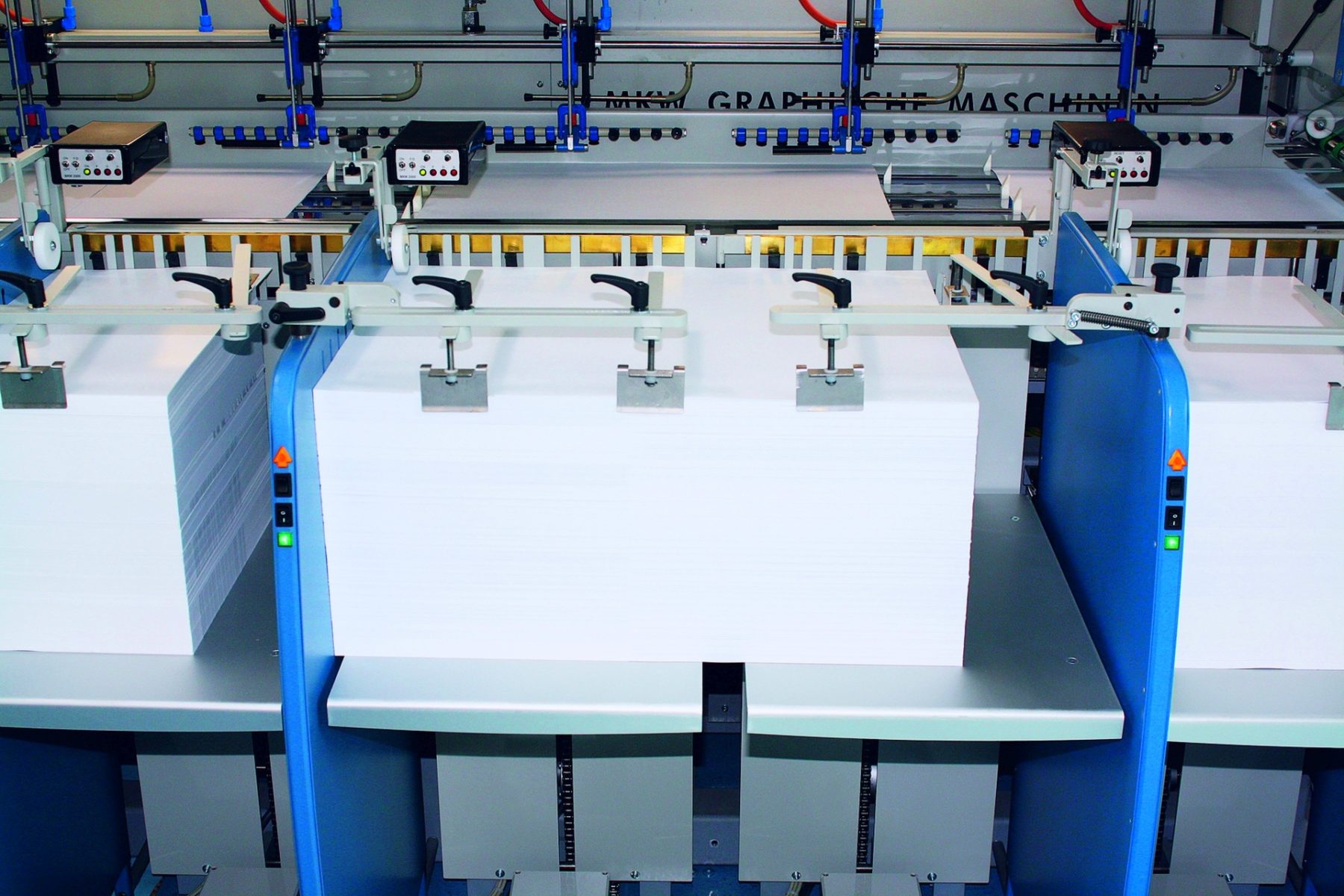

MKW RAPID UT

Our traditional system for collating printed products at high speed. The system is designed to work with media measuring from 10 x 14cm to 100 x 70cm.

The collator can be loaded using the optional pre-stacking system to reduce set-up times. The standard lines can cover up to 40 stations or more.

The machine is designed for the following sizes as standard:

- B4 25 x 35 cm

- B3 35 x 50 cm

- B2 50 x 70 cm

- B1 100 x 70 cm

- Intermediate and special sizes

Optional extras:

- DUPLEX function

- Pre-stacking system

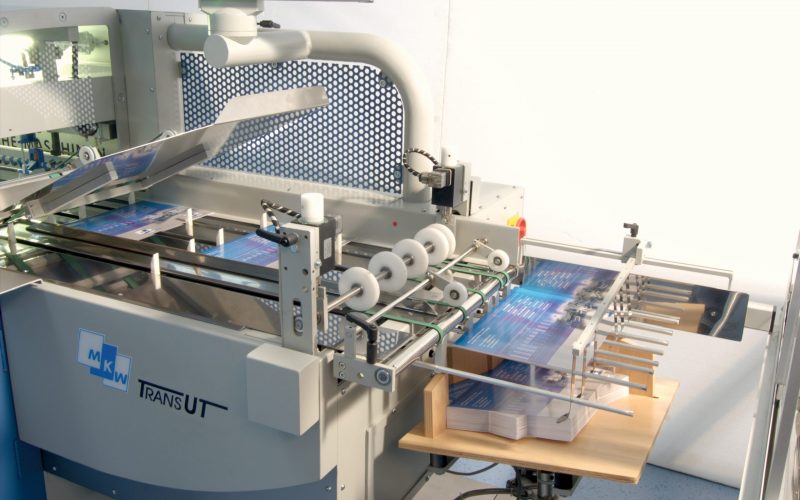

MKW TRANS UT

The innovative TRANS is a development of our RAPID model, both technically and in terms of design. It is faster than its predecessor and features more digital functionality, including partial automation. It delivers a marked improvement in production performance, not least thanks to a completely new drive system. Its standard operating range is 10 x 14cm to 100 x 70cm. The TRANS can also be fitted with a pre-stacking system.

The TRANS range is ideal for brochures and calendars, including for large print runs.

The machine is designed for the following sizes as standard:

- B4 25 x 35 cm

- B3 35 x 50 cm

- B2 50 x 70 cm

- B1 100 x 70 cm

- Intermediate and special sizes

Optional extras:

- DUPLEX function

- Envelope scoring attachment

- Pre-stacking system

If you want to watch embedded videos on these pages, personal data (IP address) is sent to the operator of the video portal. It is therefore possible that the video provider stores your access and can analyse your behaviour.

When you click on the link below, a cookie is set on your computer so that the website knows that you have consented to the display of embedded videos in your browser. This cookie does not store any personal data, it only recognises that consent has been given for the videos to be displayed in your browser.

Learn more about this aspect of privacy settings on this page: Datenschutzerklärung

Show videos

Alternatively, you can use this link, which will take you directly to the video on the video provider's website: https://youtu.be/TbTpf3a6gAw

If you want to watch embedded videos on these pages, personal data (IP address) is sent to the operator of the video portal. It is therefore possible that the video provider stores your access and can analyse your behaviour.

When you click on the link below, a cookie is set on your computer so that the website knows that you have consented to the display of embedded videos in your browser. This cookie does not store any personal data, it only recognises that consent has been given for the videos to be displayed in your browser.

Learn more about this aspect of privacy settings on this page: Datenschutzerklärung

Show videos

Alternatively, you can use this link, which will take you directly to the video on the video provider's website: https://youtu.be/fEQEZrwrHXk

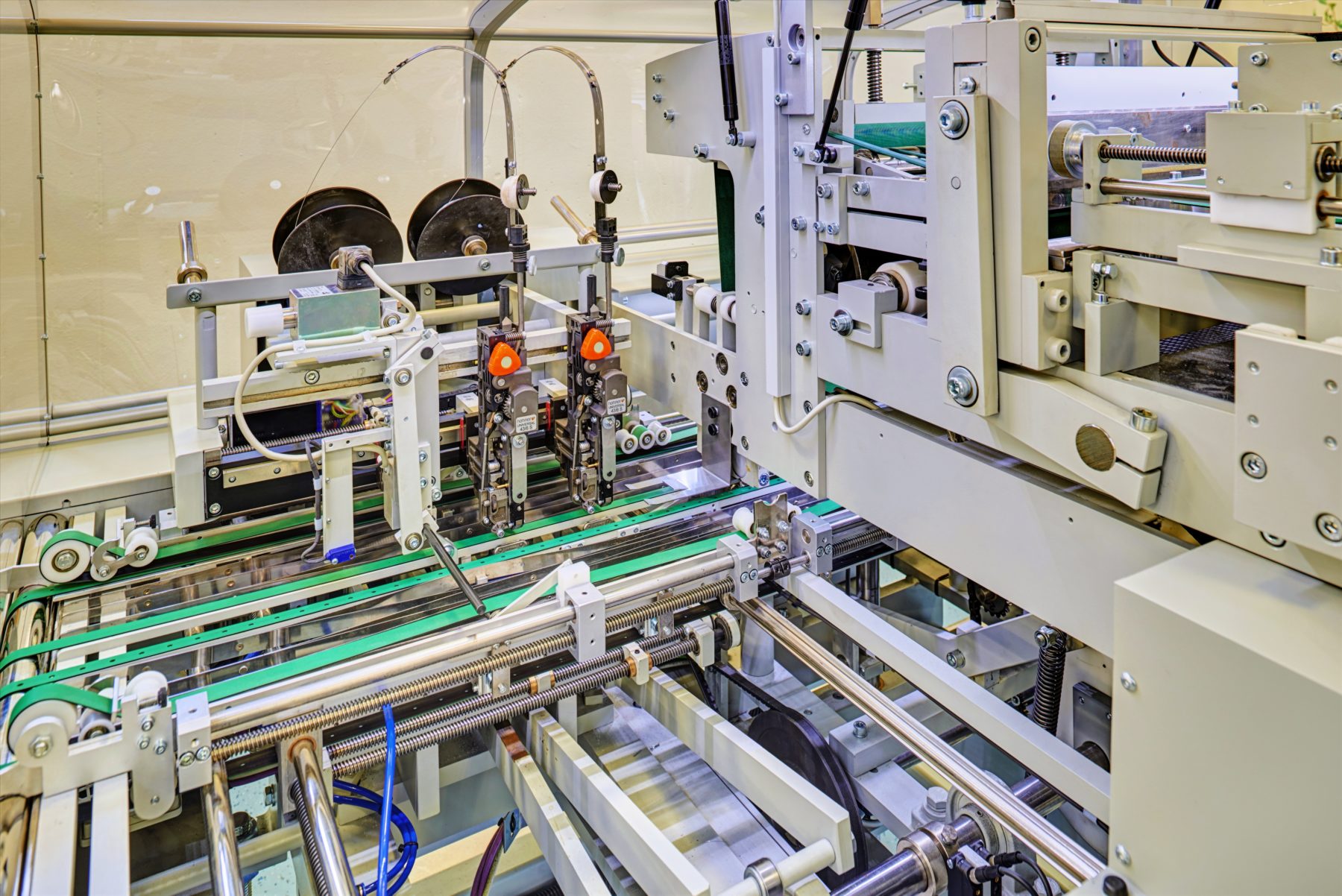

MKW RAPID UT-SC

Our Smart Collator (SC) is based on our RAPID model, and represents an intelligent step forward for collating machines. Computer-controlled collating from within a database means individually configured print runs containing different sets can be packaged in a single work step, delivering high levels of flexibility.

The Smart Collator can handle media from 10 x 14cm to 100 x 70cm, as well as special and miniature formats.

QR code scanning and tracking ensures that every individual set runs smoothly, and you can view the whole process via the control panel. All in all, this system provides a winning combination of outstanding efficiency and 100% reliability.

Labelling and bagging are done in-line using a built-in label printer and a linked film packaging machine.

These features make our Smart Collator particularly sought-after in the retail sector, because they allow retailers to deliver individually packaged advertising materials to Points of Purchase (PoP) / Points of Sale (PoS).

Optional extras:

- DUPLEX function

Pre-stacking system

- IP camera systems

- Online VPN diagnostics and 24 hours remote assistance

MKW GIANT UT

The GIANT was developed for converting large-format sheets and mixing packaging or cardboard packaging.

For example, the GIANT acts as a link between the printing machine and a die-cutting machine, be it a flatbed die-cutter or a rotary die-cutter. The pallets are transported from the printing machine to the stations of the collating machine and brought together set by set to form a perfectly aligned stack in the pallet delivery.

The particular strength of the GIANT lies in the central alignment of the stack, which ensures precise and efficient feeding of the material into the die-cutting machine.

This machine collates large-scale formats from 100 x 70cm to 145 x 106cm, and it can handle paper from 80g/m² to 1000g/m².

The GIANT can be loaded using pallets up to 140cm high and weighing up to two and-a-half tonnes.

If you want to watch embedded videos on these pages, personal data (IP address) is sent to the operator of the video portal. It is therefore possible that the video provider stores your access and can analyse your behaviour.

When you click on the link below, a cookie is set on your computer so that the website knows that you have consented to the display of embedded videos in your browser. This cookie does not store any personal data, it only recognises that consent has been given for the videos to be displayed in your browser.

Learn more about this aspect of privacy settings on this page: Datenschutzerklärung

Show videos

Alternatively, you can use this link, which will take you directly to the video on the video provider's website: https://youtu.be/wFhxs8tLFUw

If you want to watch embedded videos on these pages, personal data (IP address) is sent to the operator of the video portal. It is therefore possible that the video provider stores your access and can analyse your behaviour.

When you click on the link below, a cookie is set on your computer so that the website knows that you have consented to the display of embedded videos in your browser. This cookie does not store any personal data, it only recognises that consent has been given for the videos to be displayed in your browser.

Learn more about this aspect of privacy settings on this page: Datenschutzerklärung

Show videos

Alternatively, you can use this link, which will take you directly to the video on the video provider's website: https://youtu.be/kFFxvr-qWZI

MKW MINI-GIANT UT

The MINI-GIANT, a more compact version of the GIANT, is in no way inferior in terms of quality and reliability.

Ideal for making up stationery, color sample cards, cardboard and plastic film.

The MINI GIANT can work with material measuring 100 x 70cm or 115 x 86cm as standard.

With this range of machines, users can feed large-format system palettes into the collating machine and process them in a single step. This system can also process jobs from palette to palette, which can then be stacked using the lifter in the pre-stacking system and simply rolled into the stations by hand. It all adds up to a major reduction in set-up times.

A palette delivery system is also available, which can be off-set to separate sets as required.

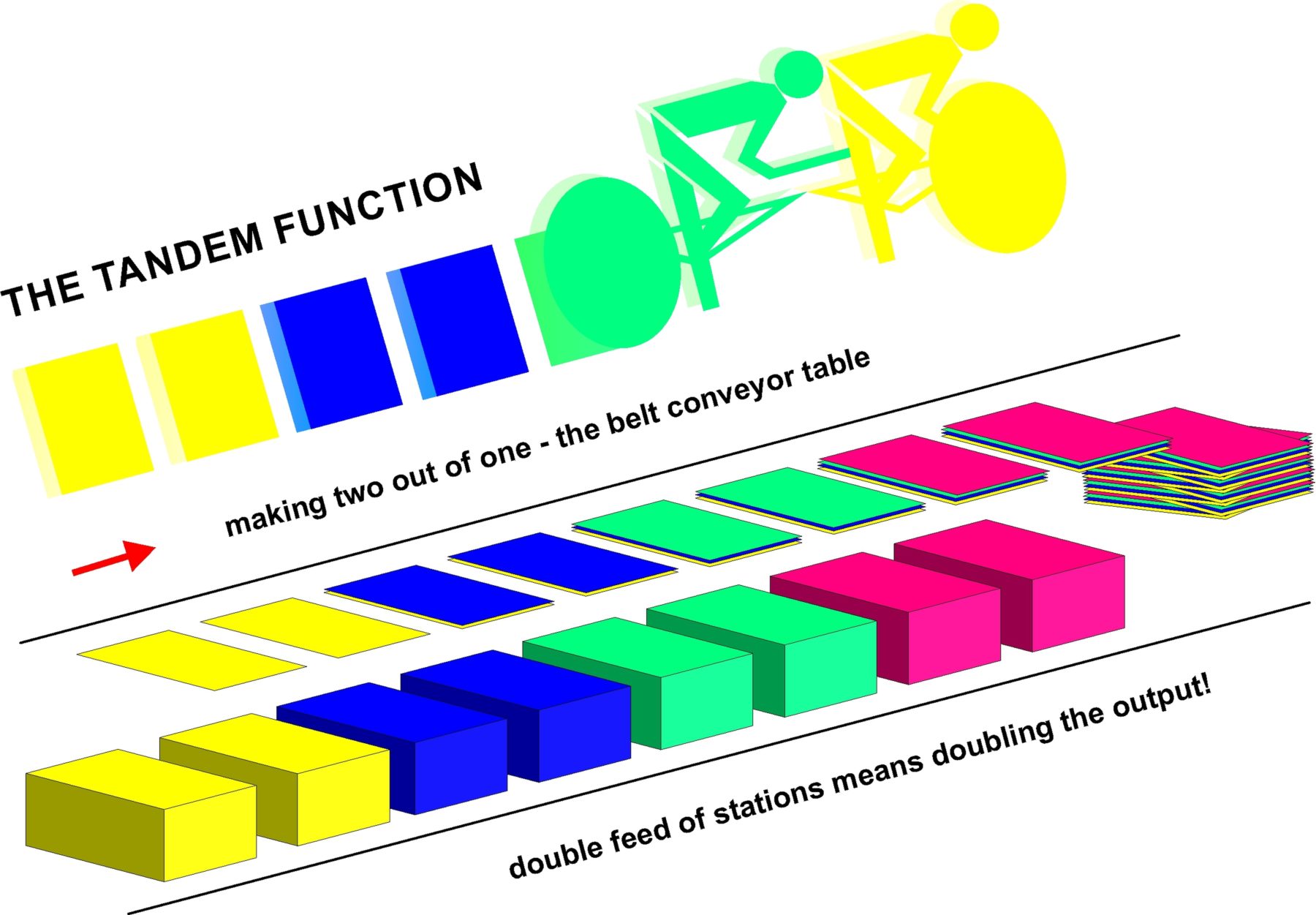

Tandem function

The collating machines can be operated in tandem mode as standard. Double loading using two stations at once increases productivity and almost doubles overall output. This feature is available as standard on most MKW collators.

Quality assurance

Missing sheet and double-sheet detectors are fitted to every station to find any defective sheets. MKW detection systems provide the highest levels of quality assurance, thanks to the following technology:

- MKW IR (infra-red sensor)

- For detecting defective and double sheets in all paper products

- MKW DUAL IR-US (infra-red and ultrasound sensor)

- Detects defective and double sheets in all paper products, as well as in plastic films

- QR or barcode scanners

- Used to register every single individual sheet

- The QR code data can also be checked against a database

DUPLEX function

- A patented MKW system to double media size and provide improved functionality

- Automatically synchronises the station desks for loading large formats

- Plug-in dividing walls, control and blower system

- Foldable transporter for flexibility and minimal loading times

- Duplex delivery systems allow you to make the most of any size or format

Digital printed brochure finishing line

Unsere Fertigungslinie zur Herstellung digital gedruckter Broschüren.

Die digital gedruckten Broschüren werden manuell auf den Handvorlagetisch platziert. Die anschließende Verarbeitung erfolgt reibungslos durch unsere zuverlässigen Nachfolgeaggregate.

Das Ergebnis? Eine vollkommen perfekte Broschüre in jeder Hinsicht.

MKW RAPID SFT

The SFT downstream machine starts the process of producing your brochures. Once collated, you can add the binding, fold and front trim of your choice. Thanks to electric servo motors, adjusting size and format settings is quick and easy.

As standard, the machine can produce brochures in the following media formats:

- 35 x 50 cm A4

- 35 x 62 cm A4 landscape

- 50 x 50 cm 2x A5 + A4

- 50 x 62 cm 2x A4 landscape

- 50 x 62 cm A3 + A4

- Intermediate and special sizes

MKW RAPID T20

When used together with the SFT, the T20 will make sure you get exactly the head and tail trim you want. Again, format settings can be quickly and easily adjusted using the electric servo motors.

The machines are set up to work with the following brochure sizes as standard:

- 35 x 25 cm

- 35 x 31 cm

- 50 x 25 cm

- 50 x 31 cm

- Intermediate and special sizes

Optional extras for individual appliances include:

- Corner perforation

- Perforation

MKW TRANS SFT

The TRANS range is built to produce brochures in large numbers, assisted by suitably adjusted SFTs and T20s.

The SFT starts the process of making your brochure. Once collated, the brochures can be given the binding, fold and front trim of your choice. Format settings can be adjusted automatically.

As standard, the machine works with brochures in the following media formats:

- 35 x 50 cm A4

- 35 x 62 cm A4 landscape

- 50 x 50 cm 2x A5 + A4

- 50 x 62 cm 2x A4 landscape

- 50 x 62 cm A3 + A4

- Intermediate and special sizes

MKW TRANS T20

When used together with the SFT, the T20 will make sure you get exactly the head and tail trim you want. As with other models, format and size settings can be adjusted completely automatically.

The machines are set up to work with the following brochure sizes as standard:

- 35 x 25 cm

- 35 x 31 cm

- 50 x 25 cm

- 50 x 31 cm

- Intermediate and special sizes

Optional extras for individual appliances include:

- Corner perforation

- Perforation

If you want to watch embedded videos on these pages, personal data (IP address) is sent to the operator of the video portal. It is therefore possible that the video provider stores your access and can analyse your behaviour.

When you click on the link below, a cookie is set on your computer so that the website knows that you have consented to the display of embedded videos in your browser. This cookie does not store any personal data, it only recognises that consent has been given for the videos to be displayed in your browser.

Learn more about this aspect of privacy settings on this page: Datenschutzerklärung

Show videos

Alternatively, you can use this link, which will take you directly to the video on the video provider's website: https://youtu.be/cpvbXeZ2yPg

Inline Cover scoring attachment

This add-on to our collating machines ensures your post-processing is just right, helping you to deliver the perfect brochure. The process is done in-line, making efficient use of time and materials.

Corner perforation and perforation

- Hole punching

- Corner perforation

If you want to watch embedded videos on these pages, personal data (IP address) is sent to the operator of the video portal. It is therefore possible that the video provider stores your access and can analyse your behaviour.

When you click on the link below, a cookie is set on your computer so that the website knows that you have consented to the display of embedded videos in your browser. This cookie does not store any personal data, it only recognises that consent has been given for the videos to be displayed in your browser.

Learn more about this aspect of privacy settings on this page: Datenschutzerklärung

Show videos

Alternatively, you can use this link, which will take you directly to the video on the video provider's website: https://youtu.be/NRcJF0KPqsA

Criss Cross Jogger

Create individual sets for small print runs and interleaved delivery, set by set. The jogger will set your media up perfectly for post-processing – even if you have more than one format in your set.

High-pile delivery unit (HA)

The high-pile delivery unit is designed for delivering large quantities of media for big print runs. It features an automatic stack changing function, and can be used as shown with the GIANT and MINI GIANT to deliver pallets.

Non-stop delivery

Our non-stop delivery system is ideal for large print runs. Feeding sheets into the machine almost continuously ensures the machine runs at maximum efficiency.

Pre-stacking systems

Pre-stacking systems make loading the machines so much faster. A variety of systems are available depending on the machine being used.The next job or further piles of the same job can be prepared and reloading times are reduced down to just a few minutes.

- Loading on pallets MINI GIANT

- Fixed pre-stacking systems are also available for the RAPID and TRANS